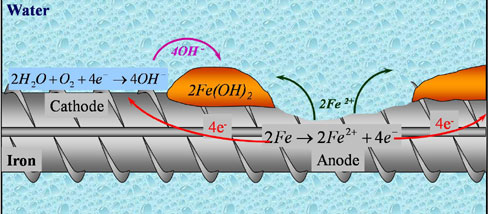

The composition of mild steel varies along its length and potential anodic more negatively charged and cathodic positively charged sites can be set up at various points.

Steal rod corrosion concrete wall.

Gilson s tamping rods are used in the consolidation of fresh concrete specimens in test applications for the slump air content and strength in accordance with many astm and aashto standards.

The rate of corrosion due to carbonated concrete cover is slower than chloride induced corrosion.

Concrete structure can be made with many different ways.

Break beyond the delimited area until reaching sound concrete and steel.

The stainless steel rods are corrosion resistant with hemispherical tips at both ends.

The concrete structure made by using the plain cement concrete has good compressive strength but very little tensile strength thus limiting its.

Vector corrosion technologies inc.

When concrete carbonates to the level of the steel rebar the normally alkaline environment which protects steel from corrosion is replaced by a more neutral environment.

Under these conditions the steel is not passive and rapid corrosion begins.

Some are given below.

Coatings on steel dowels only forestall corrosion while rjd fiberdowel eliminates it.

Corrosion engineering is a relatively new profession dedicated to slowing reversing preventing and avoiding the impact of corrosion on materials and structure.

Plain cement concrete is a hardened mass obtained from a mixture of cement sand gravel and water in definite proportion.

Nace estimates the cost of corrosion damage to concrete structures in the usa is approximately 125 billion per year.

For steel in concrete the passive corrosion rate is typically 0 1 µm per year.

Precast concrete wall solutions to fit every need quality meets design with our precast concrete walls built to match your surroundings and withstand the elements.

By using a marker pen delimit the area of damage.

Corrosion is the single most important cause of damage to concrete structures.

All weak damaged and easily removable concrete should be chipped away.

Corrosion engineers are responsible for developing coatings and treatments that can be used on metals to improve the metals resistance to corrosion.

In construction of concrete slabs expansion and contraction joints are purposely positioned in the slab where cracks in or movement of the slab will occur.

Without the passive film the steel would corrode at rates at least 1 000 times higher aci222 2001.

Realistic textures mimic the appearance of solid stone wood and brick in an endless variety of designs and colors.

Because of concrete s inherent protection reinforcing steel does not corrode in the majority of concrete elements and structures.

Corrosion protection of reinforcing steel in concrete matt miltenberger p e.